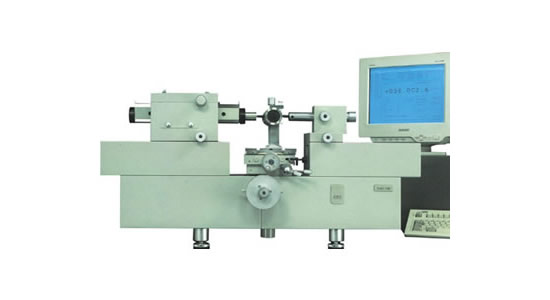

DMS680

DMS680

Wide usage area

For periodic checks of gauges, reference gauges and a wide range of measuring instruments and gauges such as plug gages, ring gages, plug gages, gage blocks, horseshoe gages, outside diameter micrometers, inside diameter micrometers, bore gauges, comparators and electronic probes.

High precision

It fully complies with Abbe's comparator principle. Adjustable work table and fixed measuring pressure 0.2 µm Heidenhain scale for easy location of the measuring point. Max. and direct reading from PC for automatic detection of min point. Gauge calibration software for the operator of all measurement procedures.

Gauge / tool management and measurement software

The device is connected to a PC to directly read the current value. The software provides unmatched support for full compliance with ISO 9000 requirements.

The operator is guided precisely through all measurement procedures.

- Automatically calculates tolerance. The formulas of the teeth are evaluated.

- Full including calibration date, location, cost center, procedure and standard records tool / gauge information.

- Tools / gauges are suitable for date, type, section, cost center and nominal dimensions classified as.

- The procedure can be recalled and displayed again during the measurement process.

- Master / tools are managed with the last calibration date and automatic date notification.

- Full traceability of the master date is provided. Each measurement operator, gauge and recorded with the machine equipment used.

- Temperature compensation function

Standard Accessories

Buffer Gauge Measuring Unit: Buffer Gauge Holder, Radius Inserts, Large and Small Edge Knife Bits

Center rail (cradle)

Ring Gauge Measuring Unit: Large Measuring Arms, Radius Tips for Measuring Arms, Small Measuring Arms with Special Point Body Spindle, Spherical tips for Small Measuring Arms, Precision adjustment ring 14 mm. and 50 mm. small and large parallels across

Snap Gage Measuring Unit: Fixing Unit with Cross Holder

Measurement Unit for Small Size Holes (Starting from 1mm): Mounting Table, Contact Probe Holder, Spherical Probe Diameter 0.8 - 3 mm.

Buffer Thread Gauge Measurement Unit: Small, Medium and Large Size Flat Contact Probes, 21 calibrated measuring wires

Buffer Pipe Thread Gauge Measurement Unit: Has the same accessories as the Tampon Thread Gauge Measurement Unit (software not included, please check the extra software options.)

Ring Thread Gauge Measuring Unit: Free-running Table, Precision Contact Spheres Set for Small and Large Measuring Arms, V-type 55º and 60º Measuring Blocks

Workshop Parallel Length Scales Measurement Unit: Fixing Unit

Outside Micrometer Measuring Unit: Micrometer Table with Measuring Arms, 4 - 12 mm. Diameter Spherical Measuring Probe, Flat Measuring Probe

Bore Micrometer Measuring Unit: Double Sided Adjustable V-bed

Fixing Unit for Parallel Length Scales: Large and Small Double Sided Adjustable V-bed

Spline Involute Dental Measuring Unit: Internal and External Profiles can be Measured with the help of Standard Measuring Wires and Spheres. (software not included, please check extra software options).

Comparator and Gauge Comparator Measuring Unit: Dial gauge holder with 8mm and 3/8 "bindings diameter

Temperature Error Compensation System

Temperature Sensor: It is placed in the Measuring Head. Working range 15 ° -30 ° C

Software: The temperature is read directly from the DMS 680 in the range of 0.01 ° C.

MicroNet2000 Software

The DMS 680 measuring unit is supported by MicroNet 2000 software for Measuring and Calibration Management of Gauges and Gages. The software works in Windows environment. The language of the software and user manuals is English.

Calibration Management (Control) Software: For calibration management of Gages and Gauges and archiving of values. Automatic tolerance calculation in accordance with ISOR-1938, ISO 286, ISO / R-1502 (check extra software options for other standards) standards. Word, Excel, PDF etc. Possibility of data transfer in various formats. Traceability in all measurements, easy finding of the measuring device or gauge in the archive.

Measurement Software: Fast and reliable measurement by means of software integrated directly with DMS 680. Instant reading of the measured value on the screen, Integrated measurement procedures, Automatic Detection of Inversion Point, Automatic evaluation of thread diameter in Thread Gages, Automatic evaluation of the measurement instruments within limits and tolerances over criteria such as Fu, Fmax, Repeatability.

Extra Accessories

T- Sphere Ring Thread Gauge Measurement Unit: Gage Diameter 3 - 90 mm., Precision measurement probe, Digital Display with anolog and Numeric Display, 0.335 - 1.350 mm. Set of 8 pairs of spherical measuring tips in the range

Ring Pipe Thread Gauge Measurement Unit: Used with the above accessories. (Height Unit and software are not included, please view other accessories)

Thread Pitch Measurement Unit: Inner and Outer Diameter Thread Pitch Measurements: For distance measurements between tooth channels. Spheres supplied as standard with DMS 680 are used. Different Spheres are available on request. Digital Display (not required if T-Sphere Measuring unit is available)

Large Diameter Ring Thread Gauge Measurement Unit: Measurement Range 90-400 mm. Spheres supplied as standard with DMS 680 are used. Different spheres are available upon request. Digital Display (not required if T-Sphere Measuring unit is available)

Sphere Holders for Outside Measurements: Spheres supplied as standard with DMS 680 are used for outside diameter measurements with spline profiles. Different spheres are available upon request.

Extra Resolution 0.01 µm: DMS 680 increases the resolution up to 0.01 µm.

Extra Weight: For Increasing Outer Diameter Thread Gauge Measuring Force up to 11 N

Height Measurement Unit for Internal Pipe Thread: Holder Unit, Heidenhain MT25B measurement probe for reading in Z axis, software for direct automatic reading. Note: The "T Sphere Ring Thread Gauge Measuring Unit" must be purchased. Gauge tolerances are not included, check out extra software.

Tolerance +/- Module: It is used in the calculation of automatic Tolerance and Measurement Formula for ISO straight Gages with special tolerances.

ANSI / ASME Tolerance Module: Automatic Tolerance and calculation of measurement formulas; Straight Gage ANSI Inch: ANSI / ASME B891,6M-1984, "Gagemakers" Tolerance Chart. Thread Gauges ANSI Inch: ANSI / ASME B.1.1-1982, B 1.2-1983, B1.13M (ISO 965-1), B.1.16M-1984

Pipe Thread Gages ANSI Inch: Automatic tolerance and calculation of measurement formulas: ANSI / ASME B1.20.1-1983, B1.20-5-1991

Gas Thread Tolerance Module: Automatic tolerance and measurement calculation according to ISO 228 standard for thread gauges and ISO 7 standards for Pipe Thread Gage.

Spline Module: Automatic tolerance calculation of spline gauges with involute profile according to DIN 5480. Automatic measurement formula for DIN 5480

Network License: DMS 680 measurement system includes one MicroNet 2000 software license. It is necessary to purchase additional licenses of MicroNet 2000 software in order to view and evaluate data from other computers in different departments. A separate license must be obtained for each computer.

Temperature Analysis Software: for recording and analysis of Temperature Data. Automatic alarm functions can be used for temperature and gradients. Temperature and gradients can be graphed.